Projects

The TurboChyll Company

Project #1 A - ECM Wind Walls

ECM Wind Wall Retrofits on 108 Data Aire Units

Project #1 B - ECM Wind Walls

Schedule:

- 6-8 Weeks Lead Time

- Install 2-3 Weeks

- New Fans in 10-11 Weeks

Cost / ROI:

- Improved operating efficiency by operating at the fan's best efficiency point and using speed control

- Improved reliability through fan redundancy

- Reduced installation costs through modular design

- Improves acoustic performance

Project #2 - Cooling Tower Replacement

Scope of Work:

Client advised TurboChyll that the Fan Motor Shaft had final broke and it was time to replace the Cooling Tower entirely.

TurboChyll hired an Engineer and Structural Engineer to develop Drawings and Plans to provide the client a price on.

Once awarded the project, TurboChyll worked to Remove the Existing Cooling Tower and properly Dispose of.

Install New Steel according to Structural Engineers Drawings.

Furnish and Install / New Cooling Tower onto New Steel with New VFD’s, New Spring Isolators, New Electrical Panels, and New Chilled Water Piping/Insulation.

After Photos of New Tower Install – Including New Steel / Piping / VFD’s

Project #3 - Le Bain VRF System

Scope of Work:

The client informed TurboChyll of the necessity for additional cooling in their upscale night club, which features an expansive hot tub. In response, TurboChyll implemented a VRF system to regulate humidity levels.

- (2) 16Ton Heat Pump Condensers

- (10) 36k Wall mounted Air Handlers

Before & After Photos of VRF System Installed

Project #4 - AHU Life Extension Project

Scope of Work:

- Provide Labor to Test and perform total air flow traverse SU-1 measurements for before work starts.

- Disconnect & Demo existing Fan Section. Properly Dispose of.

- Supply and deliver the below ECM Fan Array shown in Equipment List expediting 12 weeks included.

- Supply Labor and Materials to Install new EC Fan assembly to existing.

- Electrician by others to install all required wire for the EC fan assembly into unit.

- Furnish and Install Premium Controls with EC Whips & Dampers if required

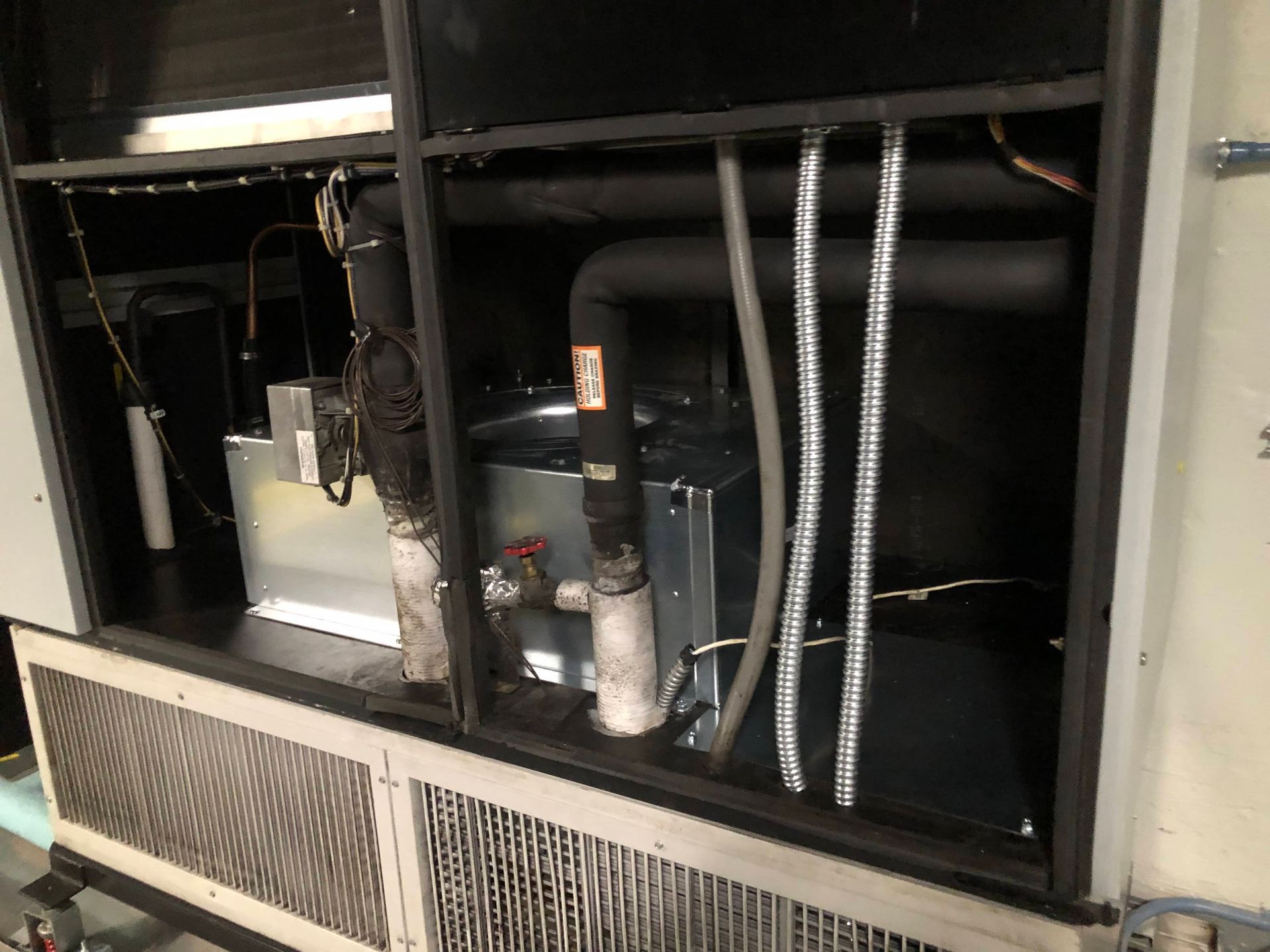

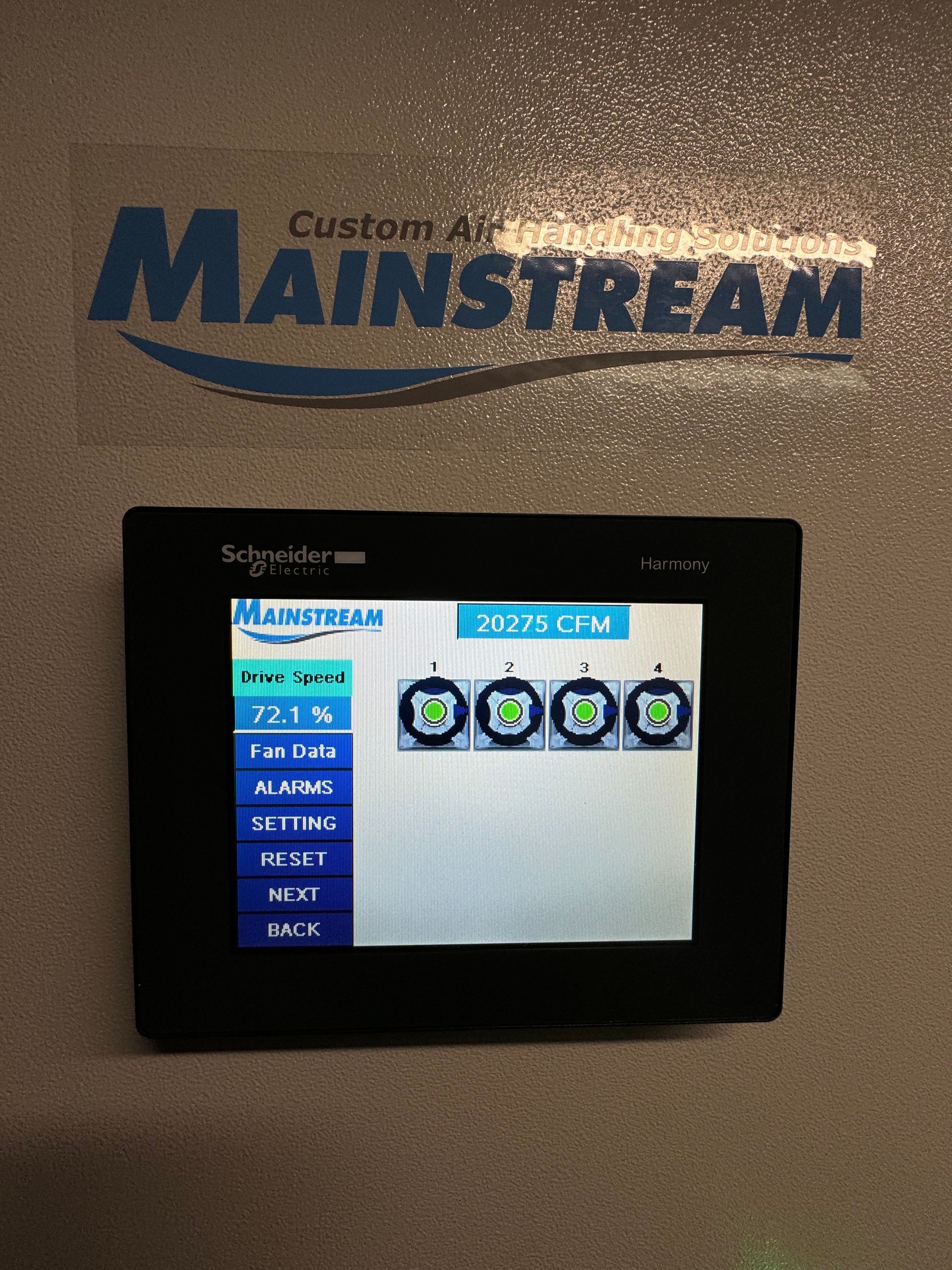

On-Going Project Photos

Project #5 - 10 Ton Unit–Supplemental Cooling

Scope of Work:

- Disassemble and remove existing 10 Ton Main for Rack Room Chilled Water Air handling unit and properly dispose of.

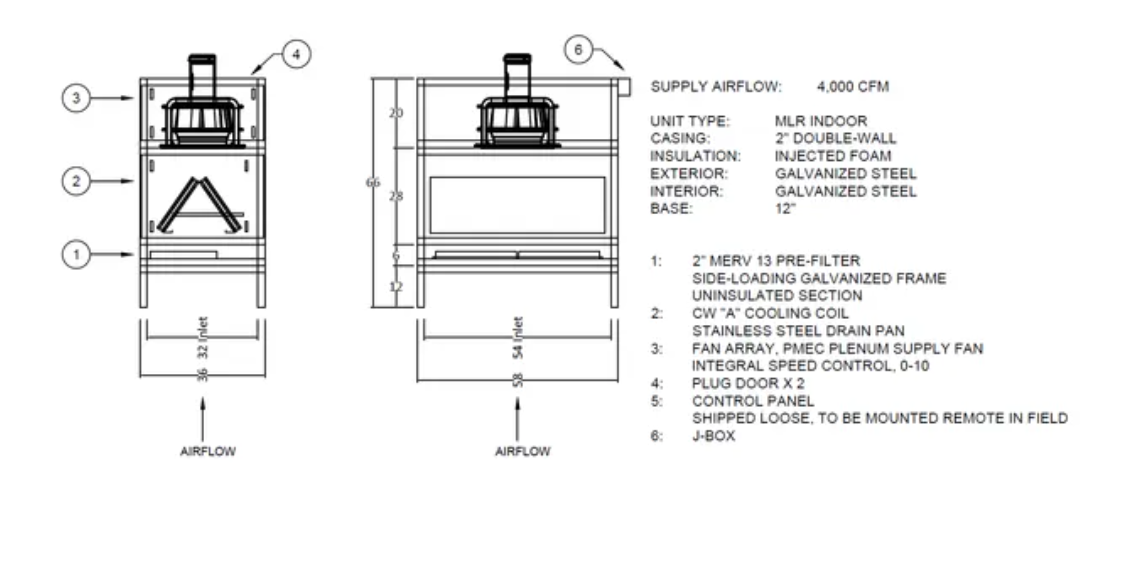

- Furnish and Install (1) Custom Indoor MLRa Supplemental 10 Ton AHU to include the following:

- 2” Double Wall Construction

- Custom stand/base to allow bottom intake

- Filters (2” MERV8)

- “A” style chilled water coil

- Fan & a humidifier shipped loose to be installed in duct

- The approx. dimensions are: 64” High (12” stand) x 62” Wide x 36” Deep

Includes Packaged Controls:

- Touchscreen Sensor

- Chilled Water Valve (24V)

- Programming - Reconnect existing piping as required. Re-Insulate existing piping if required.

- Furnish and Install Ductwork to connect to existing.

Completed Project Photos

Design:

Project #6 - VRF Design

Scope of Work:

Furnish & install LG split heat pump system to include:

- (2) 4 Ton Condensing Unit

- (4) 2 Ton Ceiling Cassettes

- (4) Thermostats

- (2) Y Branch Boxes

Mount (2) 4 Ton condensing unit on rooftop includes roof rails, TurboChyll will drive holes into roof to mount rails.

Ceiling Mount (4) 2 Ton air handler cassettes in the apartment area. Final designation of location will be provided / verified by Architect / Engineer of Record.

Furnish & install all needed & required refrigerant piping.

Before & On-Going Project Photos

Projected Finished Project Photos